Back in 1901, a Massachusetts inventor named John Perry filed a patent for an advanced machine that allowed metal workers and welders to weld together wires in sheet form for various applications. This invention was a landmark event for the industry that saw welded wire mesh sheets be produced more quickly and used in more complex applications like concrete supports. Today, welded wire mesh sheets can be seen frequently in all sorts of construction projects, big and small.

What Are Welded Wire Mesh Sheets?

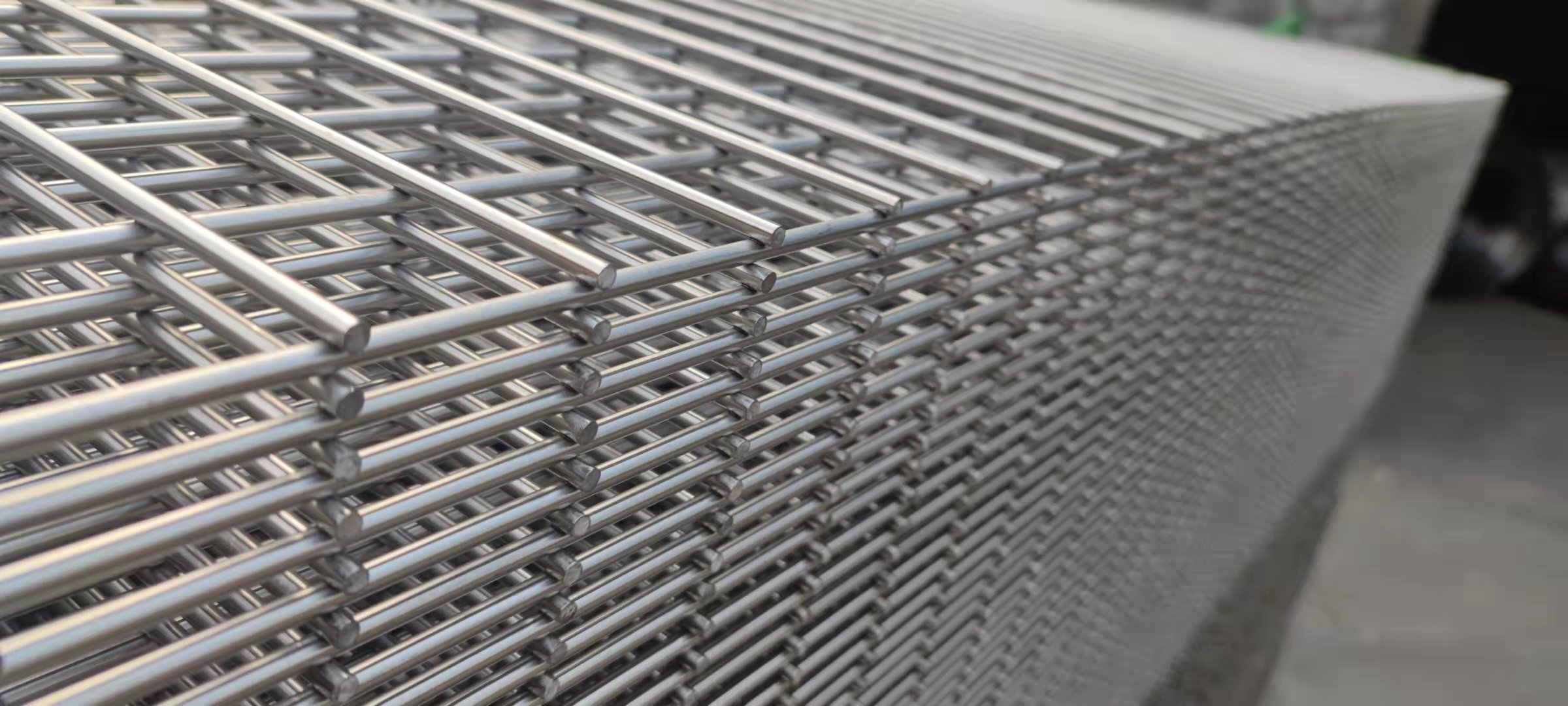

Welded wire mesh sheets are created from wires that are welded together at their cross points to form a grid-like pattern. The welding technique used is resistance welding to properly create a sheet from raw materials. The wires of the grid are guided through using a pattern board which allows the two planes of wires to form and fuse into a complete welded wire mesh sheet.

What Raw Materials Are Used?

Many different raw materials can be used to create welded wire mesh sheets. The basis of choosing what material depends on the application and setting that the finished welded wire mesh sheets will be used for.

One form of raw material that can be used is plain steel. Plain steel has a fairly low carbon content rating and is known for its value for the price. However, plain steel can rust easily if used in certain outdoor conditions.

Another form of raw material that can be used is stainless steel. Stainless steel is pricier than plain steel but more durable. Stainless steel is resistant to corrosion and offers aesthetic properties that soothe many tastes. Stainless steel is resistant to corrosion due to the presence of chromium in the chemical makeup.

Weathering steel is a raw material that can be used in the creation of welded wire mesh sheets as well. Weathering steel is utilized when natural weathering from the earth is a concern. Weathering steel develops a rust-like color when under the influence of weathering to help protect the structure of the steel.

Pre-galvanized is a form of a raw wire that has a zinc coating applied before the welded wire mesh sheets are developed. Pre-galvanized is a tiny bit more expensive than the cheapest option of plain steel. The pre-galvanized material has slightly more corrosion resistance properties and is a better base for powder coating and other aesthetic finishes.

No matter the raw material used, a variety of finishes can be performed that enhance aesthetics or add extra protection to the welded wire mesh sheets. Some of these finishes include powder coating, plating, and dipping.

If you have any questions regarding welded wire mesh sheets, reach out to Gehret Wire Works at 215-236-3322!